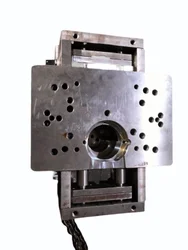

High-Pressure Die Casting (HPDC)

Your Solution for High-Quality Metal Parts

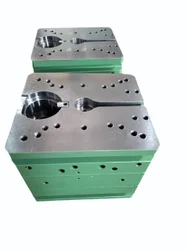

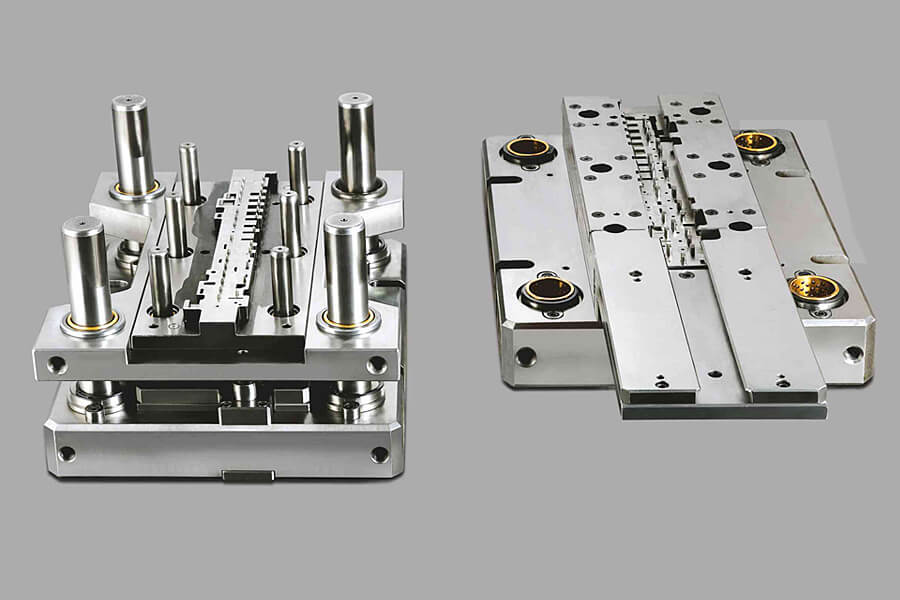

Anusha Engg Industries is a leader in High-Pressure Die Casting (HPDC), specializing in the production of intricate and high-quality metal components. Our state-of-the-art technology allows us to produce parts with exceptional precision and excellent surface finish, making HPDC ideal for industries such as automotive, aerospace, and electronics.

Key Benefits of Our HPDC Solutions:

Rapid Production: High-speed manufacturing process that reduces lead times and meets tight deadlines.

High Accuracy: Consistent dimensional accuracy and tight tolerances for complex geometries.

Material Versatility: Capability to work with various alloys, including aluminum and zinc, to meet specific application needs.

With our expertise in HPDC, we deliver reliable solutions that enhance your product performance. Contact us today to learn how our high-pressure die casting services can elevate your manufacturing processes!